BF Machinery

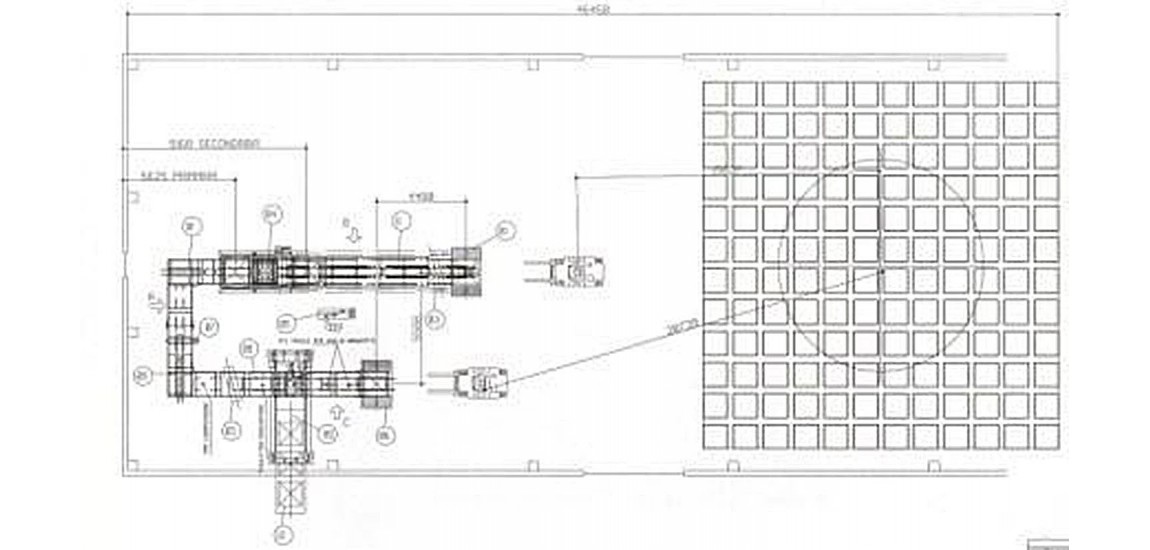

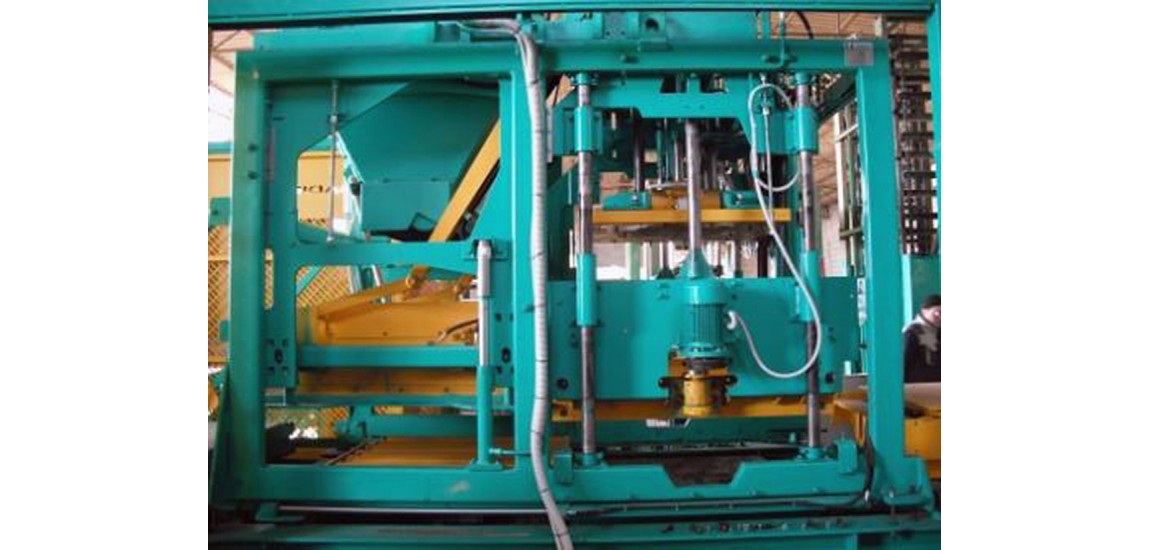

BF is the innovative stationary evolution of BadinBlock and it permits many new advantages , compared to traditional stationary plants

TABLE. The machine presses the paves and blocks on a own vibrating steel plate and only deposite the items on the wooden tables cm 120x120. The machine presses the curbs on the table, but there are no vibrators under it and the table is supported by a sturdy flat surface. All this translates into lower consumption and deformation of the plates themselves. So it is not strictly necessary to provide a system to reverse the tables around the plant.

ENERGY SAVING. The machine uses a combination of pressing (max force 50KN), side vibration, higher vibration and lower vibration on steel plate (total vibrators'force 150KN). This system can produce all the items from paves to curbs, using less power (about 30 KW on the whole machine) when compared with the same size and common stationary presses with vibration under table.

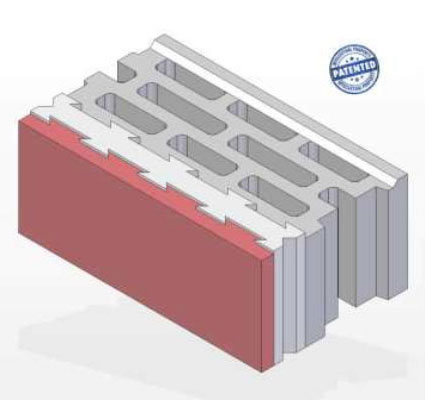

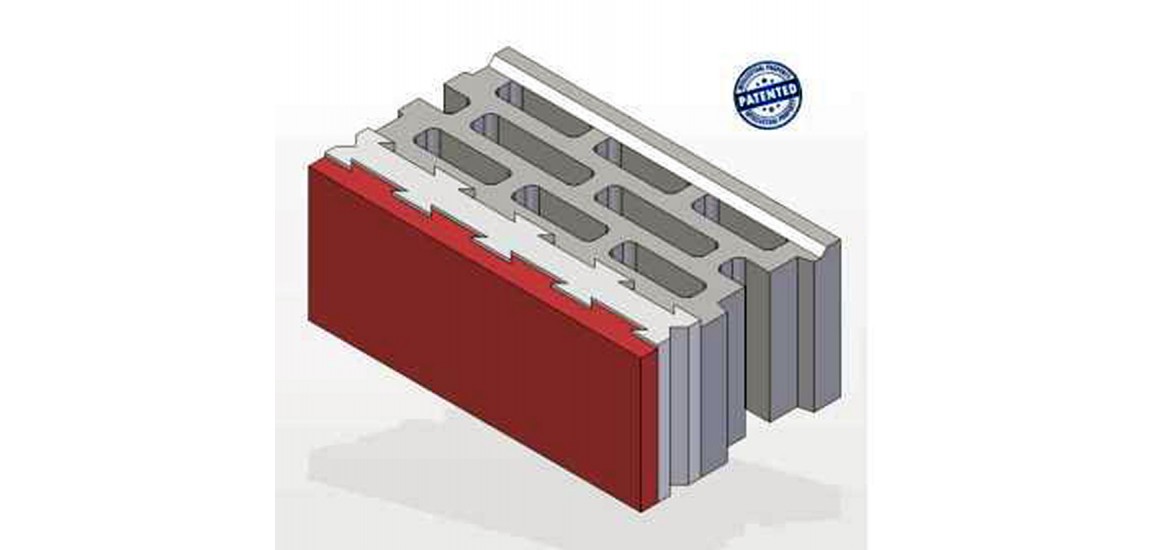

EXTREME FLEXIBILITY. The system is universal , so it's able to produce any type of product: paving, block, curb, etc.. And with additional modules: double-layer paving, curb double-layer block with thermally insulating insert and even insulated block with double-layer vertical (exclusive and patented).

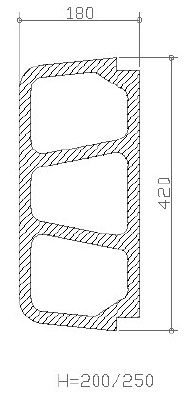

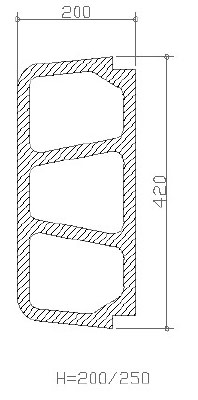

| Moulds BF | ||

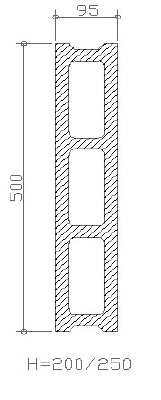

| 10 X 20/25 X 40/50 |  |

18 each time |

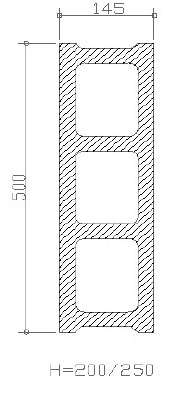

| 15 X 20/25 X 40/50 |  |

14 each time |

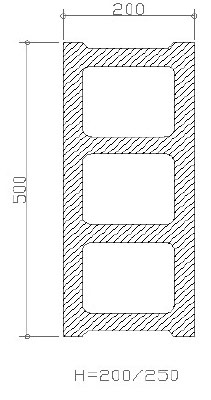

| 20 X 20/25 X 40/50 |  |

10 each time |

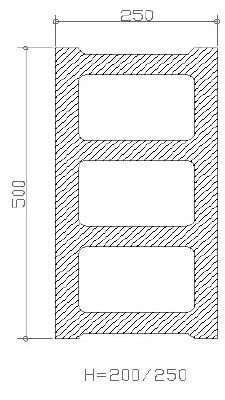

| 25 X 20/25 X 40/50 |  |

8 each time |

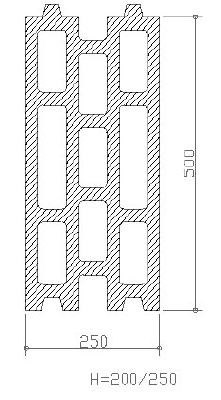

| 25 X 20/25 X 40/50 Multicellular |

|

8 each time |

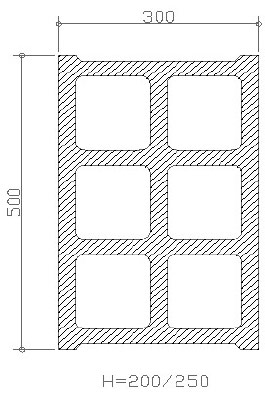

| 30 X 20/25 X 40/50 |  |

6 each time |

| Hollow Tiles | ||

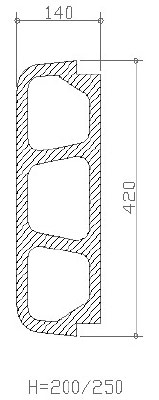

| 14 X 20/25 X 40/50 |  |

14 each time |

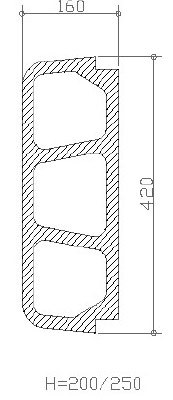

| 16 X 20/25 X 40/50 |  |

12 each time |

| 18 X 20/25 X 40/50 |  |

10 each time |

| 20 X 20/25 X 40/50 |  |

10 each time |

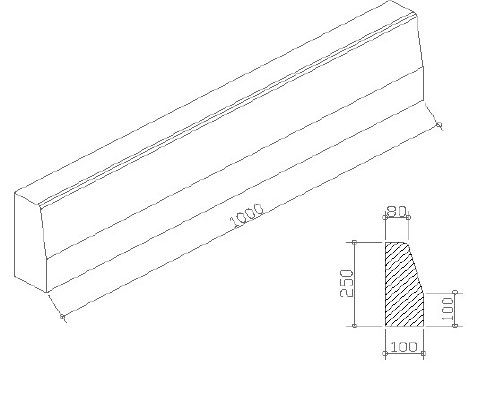

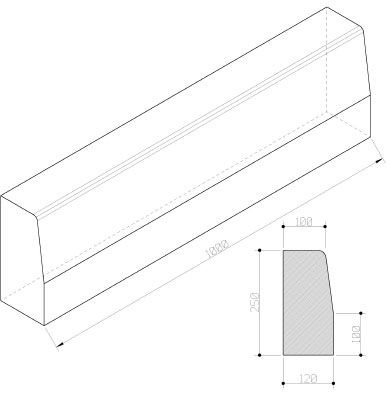

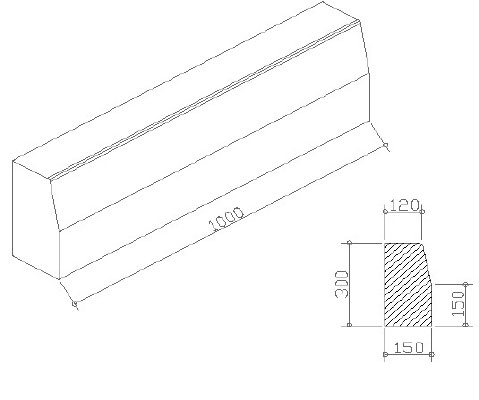

| Kurbstones | ||

| 8/10 X 25/30 X 100 |  |

9 each time |

| 10/12 X 25 X 100 |  |

7 each time |

| 12/15 X 25 X 100 |  |

6 each time |

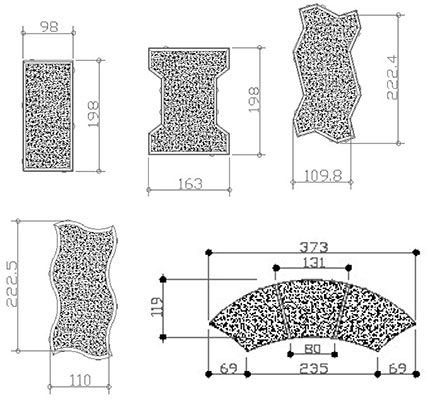

| Interlock Paves | ||

|

H60 1 m2 each time |

|

| H80 1 m2 each time |

||

| BF | ||

|

Output/day (one 8-hours shift) for 20x20x40 standard blocks | 8.000 |

|

Output/day (one 8-hours shift) for cm 12/15x25x100 kerbstones | 5.000 |

|

Output/day(one 8-hours shift) for singler-layer pavers (m2) | 600 |

|

Insulating blocks with polystyrene cm.20x20x40 | 5.500 |

|

Output/day(one 8-hours shift) for doube-layer pavers (m2) | 450 |

|

Double layer insulating blocks with polystyrene cm.20x20x40 | 4.000 |

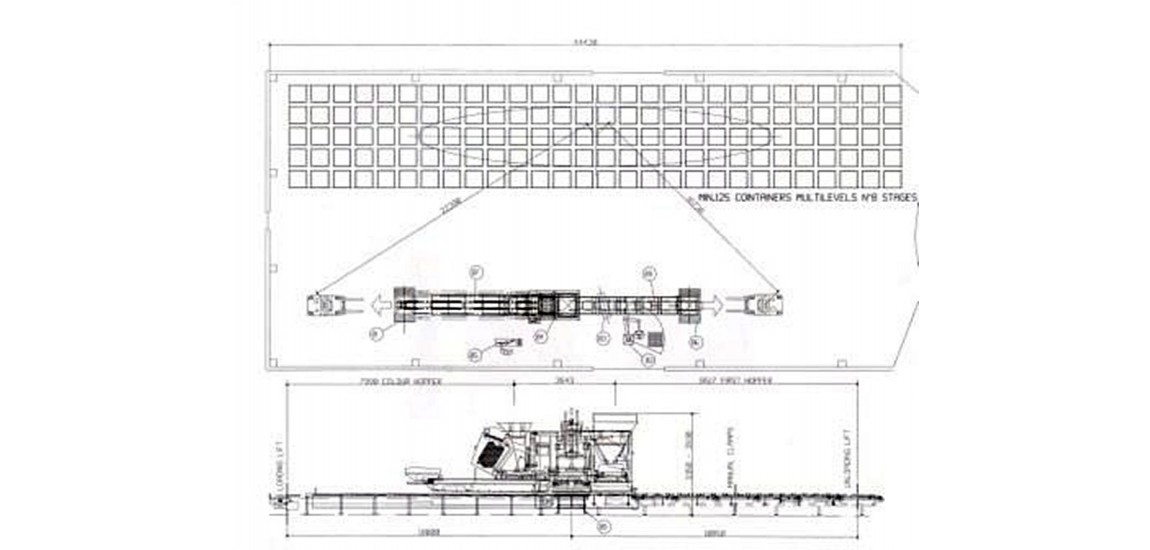

| Mould area (cm) | 105x107 | |

| Producy height (mm) | 25/300 | |

| Wooden tables (cm) | 140x120xH4 | |

| Operation | Fully automatic - PLC | |

| Total power of plant (kW) | 40 | |

| Vibro compressing force (kg) | 25.000 | |

| Weight of machine without concrete (kg) | 13.000 | |

| Hopper capacity (lt) | 1.250 |

-1150x550.jpg)

-1150x550.jpg)